I hope everyone is doing well this second week of Robot build season. Last week and possibly early this week everyone should have a chassis planned, a way to get up and down the field, and maybe some way to get the balls to a hoop.

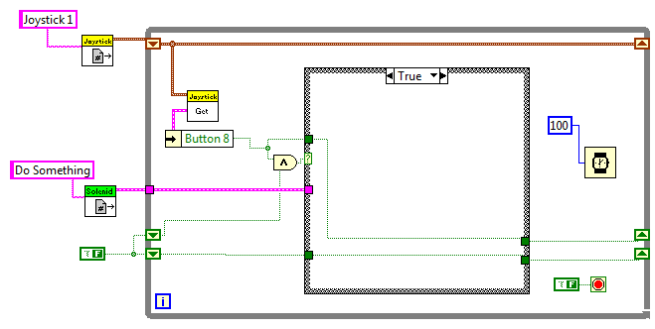

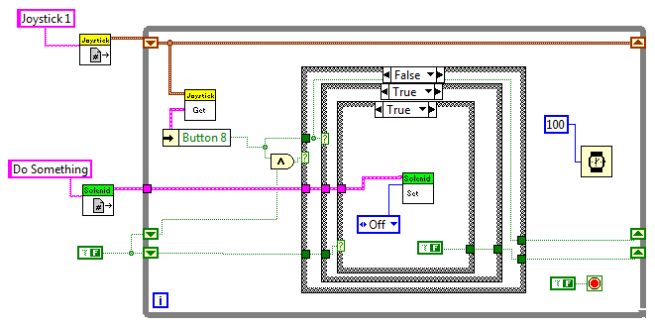

But first, a lot of people are having trouble setting up the cRio and LabVIEW software. I’d like to suggest to RTM (Read The Manual). Most of the information is in the document at this link (https://decibel.ni.com/content/docs/DOC-20204)

On with prototyping: You don’t necessarily need to do everything in the game. If you’re a rookie team you might think about doing one thing very well. One thing that can be helpful is getting the balls from one end of the field to the other. Or you might play defense well, keep the balls from moving or have some type of shield that moves up to 84 inches to block shots.

No matter what, by now you should understand the game and how you plan on playing it.

When you know how you want to play the game and are designing your robot to play you should brainstorm on how to get your robot to do it. Prototyping is a way of trying out thing quickly before going to the time and expense of building it on your robot.

To prototype, decide what you are trying to test to see if it would work, quickly build something out of wood or plastic that is approximately what you want and try it. Sometimes parts are C-Clamped together or tied with rope.

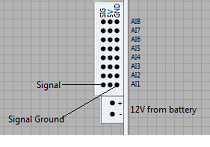

One example is a couple of years ago on Breakaway, we were prototyping a ball kicker. First we rigged up some pneumatics on the kitbot, held a pneumatic cylinder by hand and punched the ball. It didn’t work well. We then screwed a frame down to the floor (Our Robot room is an old trailer), took some surgical tubing, rigged up a wooden kicker on a long meddle screw. We would pull the kicker by hand and see how well it would work. We the switched the surgical tubing to pneumatics and tried it again. We liked the pneumatics the best. It took about 5 hours to try everything, we didn’t waste time building a full robot part to see if something worked or not, and we had a pretty good robot that could score from two-thirds of the field and move the ball the full distance.

Good luck to all